Engineering & Technology

Engineering and Technology Development • Mechanical Engineering • Mechanism Design • 3D CAD Modeling • Proof of Concept Breadboards • Design for Manufacturing (DFM) • Electrical Engineering • PCB Design • Component Specification • Firmware Development

Nearly every product requires some level of mechanical engineering, from the simplest of consumer products, like a toothbrush, to a complex medical device like an infusion pump.

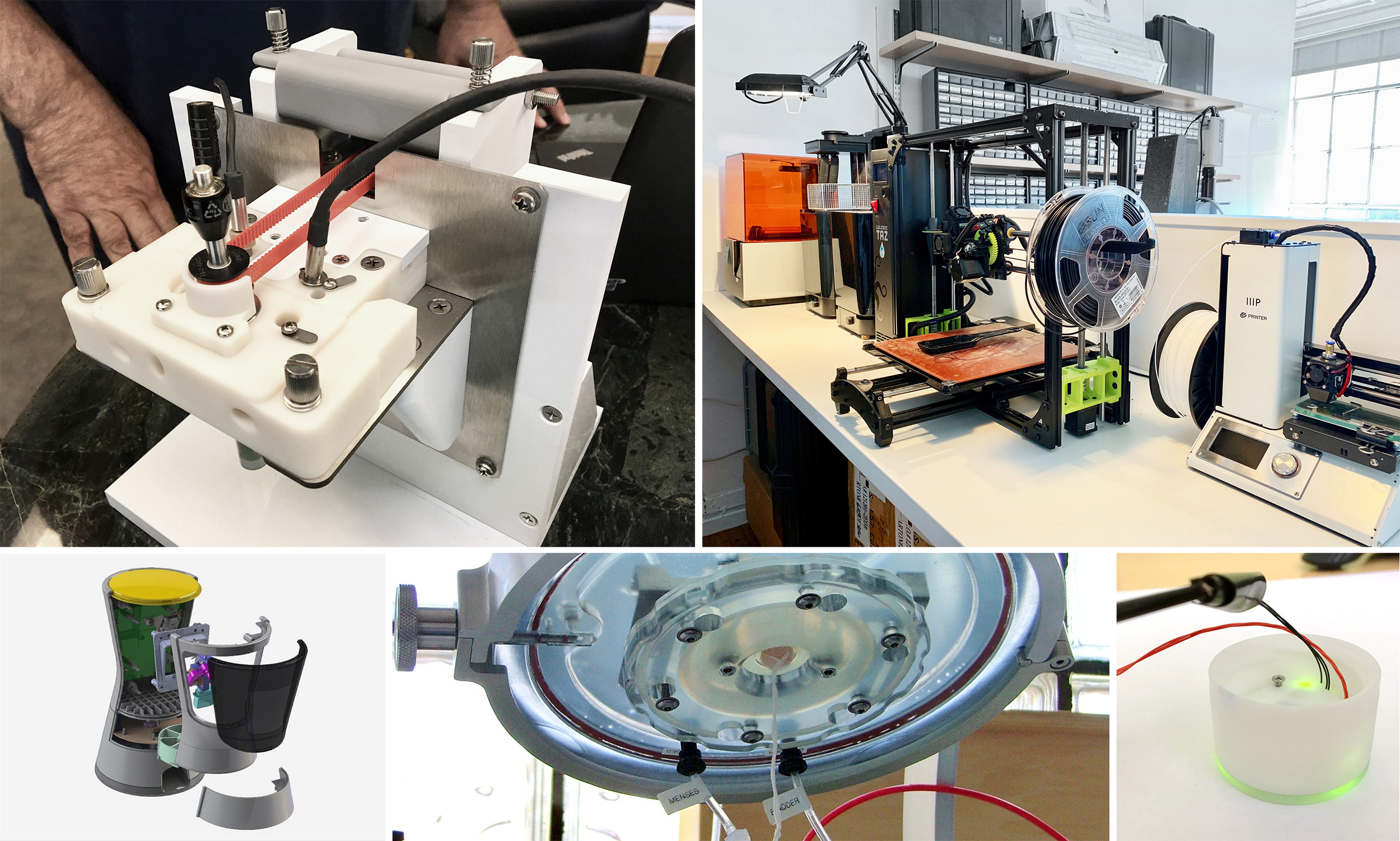

At ION, we don’t just design products; we make them real. Our strength in conceptualizing is complemented by our depth of experience in engineering and execution. This make-or-break development step is all about integrating design with technology for efficient production. It involves core technology development; material and production method specifications, CAD models, prototype fabrication, performing validation, testing and sweating the many details to assure that the final product will perform as intended.

Electrical engineering involves the design, specification and testing of all electrical system components within a product, including displays, sensors, motors, printed circuit boards, switches, processors, power supplies and related firmware. Additionally, many ‘smart’ products are mobile device connected, adding another layer of complexity to PCB and firmware design. Especially in products that involve user interactions, electrical engineering must seamlessly integrate with industrial design and mechanical engineering requirements. For this reason, ION’s electrical engineers do not work in a vacuum; they are team members who are involved from the early stages of a project.